OUR BUSINESS

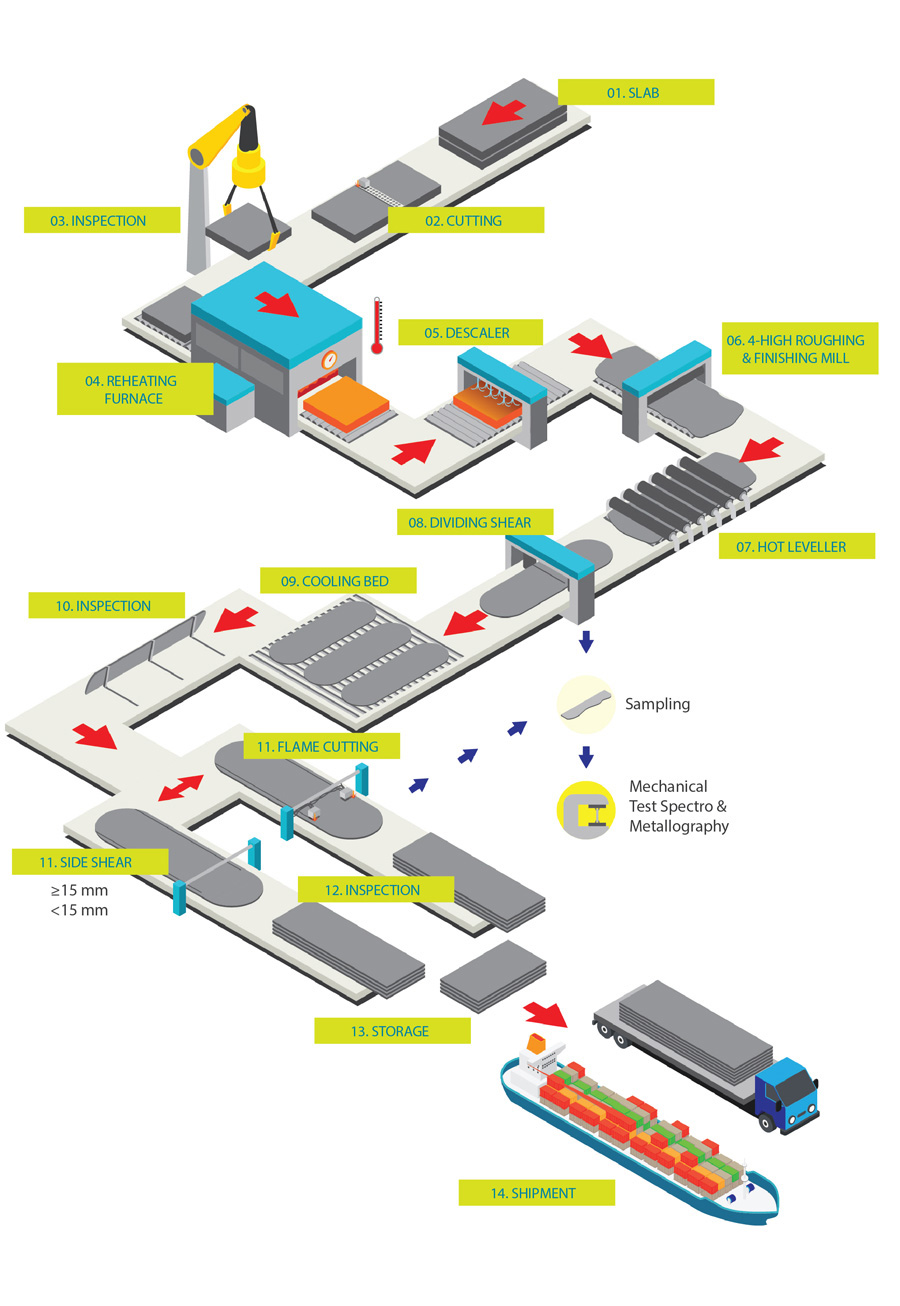

1. Slabs

Slabs are imported from international reputed sources.

2. Slabs Cutting

Slabs cut to fit the plate orders.

3. Inspection

The cut slabs are checked before further processing.

4. Reheating Furnace

The cut slabs are heated in a Furnace to predefined rolling temperature, depending upon grades and sizes.

5. Descaler

Heated slabs are cleaned using descaler machine to remove scale from previous process.

6. 4-High Roughing & Finishing Mill

The descaled slabs are being rolled by a 4-High Reversing Roughing & Finishing mill.

7. Hot Leveler

To ensure excellent plate flatness and surface quality, the hot leveler machine is used.

8. Dividing Shear

The long hot plate is then cut into shorter plates by dividing shear machine.

9. Cooling Bed

Cooling bed helps to cool the hot plates into ambient temperature.

10. Inspection

The cut slabs are checked before further processing.

11. Plate Cutting

The steel plates are cut according to required sizes. 15 mm or thicker plates are cut using flame cutting, with LPG or oxy-acetylene torches. Plates that are less thick than 15 mm are cut by mechanized side shear.

12. Stenciled

The top of all finish plates are stenciled.

13. Inspection

Plate sampling from final product are tested in laboratory.

14. Storage

The finished products are stored and ready to deliver.

15. Shipment

High quality, ready-to-use plates are then shipped to customer's place.

EN

EN ID

ID